PROPOS in your job shop

PROPOS brings QRM production planning to the workplace. By using our easy-to-use touch screens, your employees immediately see which orders are the most important, based on the planning. Your employees no longer have to ask the production manager or planner which job to work on, but will automatically start working on the correct production orders.

QRM production planning on the shop floor

The first job on the PROPOS screen is always the best choice to work on. With one tap on the screen, your operators start production on an order. Ready?

One more tap on the screen and they mark the task as completed. It is clearly visible to which production cell (categorized by different processes) the order has to go now. Your production employee brings the order to the next production cell and reports it in the buffer. This way, you always know where each order is and what the status is.

Real-Time Overview

Your production employees see real-time changes in the planning. The most important order is always the best choice for the planning. Urgent orders are processed automatically.

Less Overtime

PROPOS plans orders, automatically scheduling backwards from the delivery date. As a result, every order goes into production at the right time, and overtime is much less common.

Working more independently

Practice shows that production employees like being able to work more independently. They take more responsibility and feel more involved.

To work more efficiently

No more unnecessary searching for missing parts, or starting orders that are not yet in production. No longer waste time on unnecessary actions.

PROPOS in the workplace

One of the unique aspects of PROPOS is its integration with the shop floor. In fact, that is what PROPOS is all about: your star team of players in the workplace.

Through extremely user-friendly touch screens, PROPOS shows the operators the information that is relevant to them. They always work on the right job. Is an order threatening to arrive too late? Your workers will see it immediately on the screen, so they have the opportunity to do something about it on time. Furthermore, the monitors in your factory ensure total openness and involvement on the production floor.

Hot orders are a thing of the past

You can say goodbye to “rush orders”. They no longer disrupt your production process.

Through PROPOS, the most important order always appears at the top of the screen in every part of your factory. This way, it will roll through your production at maximum speed.

In addition to information about current production orders, your employees also see what the predicted workload is for them in the coming period. This allows them to better assess how busy it will be, whether they have to work overtime and whether or not there is room to take days off. Awareness and personal responsibility are encouraged.

Articles

Merrem Kunststoffen is Europe's top player in the processing and supply of technical plastics. With advanced machinery and 24/7 production, the turning and milling company is fully committed to robotization and automation as the key to success. 'Within 2 days we were live with PROPOS, with no downtime. We soon noticed that the production numbers went up and the flow is a lot better.'

‘Too much work in progress (WIP) is causing exploding lead times’

A shop floor full of orders and machines that are scheduled at a maximum capacity; it seems an ideal image for a shop floor to be busy and to get the most out of your machines. In practice, however, this leads to unnoticed negative consequences. Long lead times, employees searching for missing parts and work that stands still for an unnecessarily long time. And that results in customers having to wait too long for their orders. Quick wins can be found in tackling work in progress. In fact, less work-in-progress means better workflow and shorter lead times.

Customer case System Flex: shop floor control and automation of processes

System Flex produces state of the art partitions and ceilings. Custom made, with their own glassware and window frames. All this with a delivery time of just three weeks. With PROPOS those delivery times are more easily achieved. In addition to our fully automatic shop floor control, we have implemented custom apps for the automation and digitalization of production process, saving a lot of time for System Flex. Sven Damen, Project Coordinator: ‘From the first week that we went live, we saw improvements.’

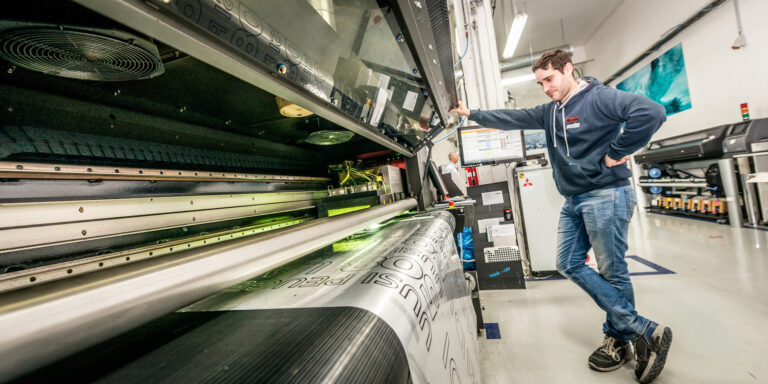

Customer case OTM-Zenith: shop floor control for the printing industry

OTM-Zenith from Brussels is the Belgian market leader in the stickering and decorating of machines, vehicles and buildings. Think of signage materials for ambulance and police cars, but also decorative and functional materials for the automotive industry and machine builders. In addition, OTM is the supplier of the official Belgian license plates. Every day, about 700 orders are in production, in varying sizes, over different stages. "Then you need a system that can handle such a volume," emphasizes Managing Partner Kurt Persoons.

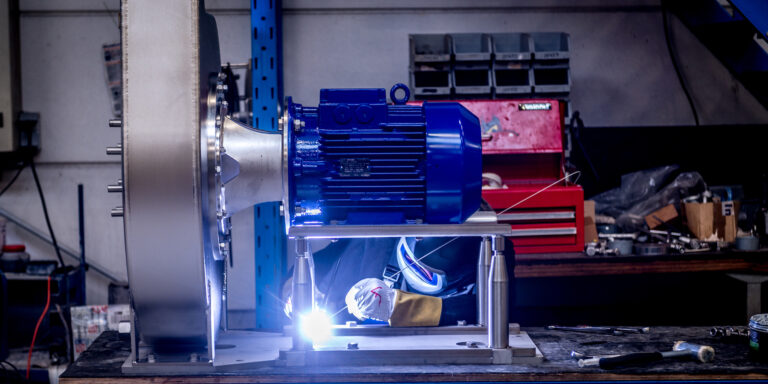

Customer case PMC: shop floor control and QRM

PMC has been a well-known name in the metal industry of West Flanders for over 30 years. Based at a brand-new location in the old Philips R&D building in Bruges, they recently started working exclusively as a job shop for Pattyn, a world player in the field of packaging machines and lines. Not so long ago, Jan Pauwels, Managing Director, changed course from large production quantities to smaller batches with a large variety: "QRM turned out to be the solution. With PROPOS we are taking the next step to work even more conveniently and faster".

Productieprocessen automatiseren met de Custom Apps van PROPOS

Een digitale fabriek met PROPOS? PROPOS maakt het werk voor productiebedrijven een stuk makkelijker. Duidelijke prioriteiten op de werkvloer, een volautomatisch aangestuurde planning en waardevolle data inzichten in uw gehele productieproces voor continue verbetering. Maar waarom zouden we daar ophouden? Met onze Custom Apps is het mogelijk om elke gewenste functionaliteit in PROPOS te integreren. Dit zorgt ervoor dat u veel productieprocessen kunt automatiseren. Van kwaliteitsmetingen tot het afboeken van materialen. Eén systeem voor uw hele bedrijf. Op weg naar een volledige Smart Factory!

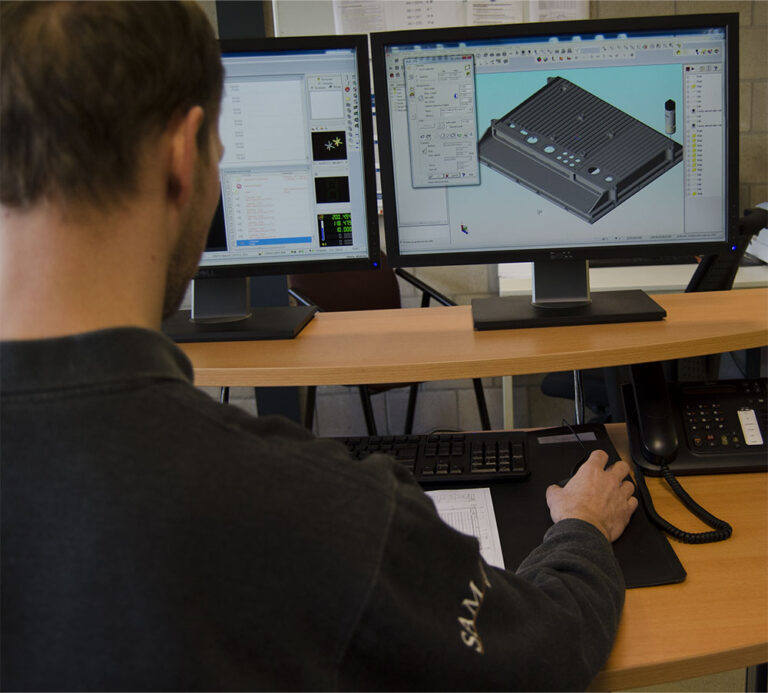

SAM Precision: waardevolle data inzichten met MKG

Welkom SAM Precision! SAM Precision uit Cuijk is specialist in het verspanen van exotische materialen t/m 54 rockwell. Met een focus op draaien en frezen kenmerkt de productie zich door high-mix low-volume. Met PROPOS gaat SAM Precision voor minder onderhanden werk en kortere doorlooptijden. Daarnaast kiest het bedrijf voor waardevolle data inzichten met de inzet van de aanvullende modules Medewerkerregistratie en Geproduceerde Aantallen én nachtelijke monitoring van hun draai- en freesmachines, dankzij een koppeling met hun ERP MKG-5.

Lean of QRM? ‘Neem het beste van beiden’

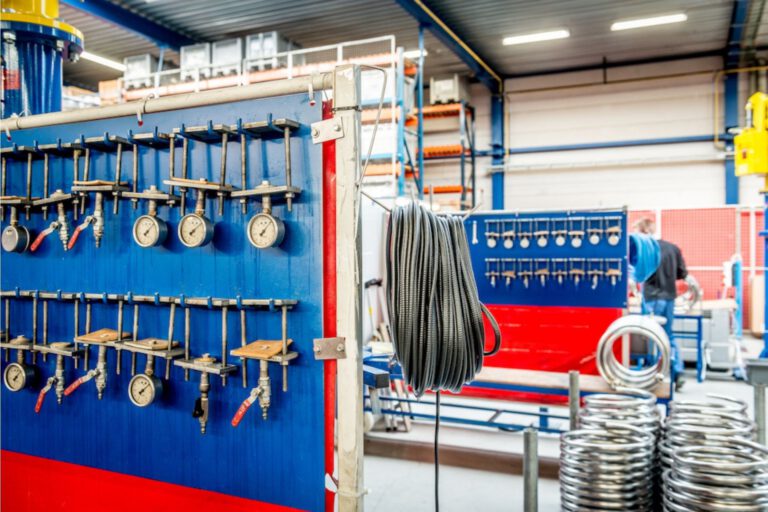

Lean of QRM? Wij vroegen het Packo Inox. Het metaalbewerkingsbedrijf uit Diksmuide produceert industriële pompen en hygiënische componenten voor de voedingsindustrie. In hun drive om continu te verbeteren ontwikkelde het bedrijf een eigen variant op Lean en nam het de eerste stappen in QRM met behulp van het shop floor control systeem van PROPOS. Is het bedrijf nu helemaal overgestapt op QRM? Nee, zo legt Managing Director Danny Maenhout uit: ‘Waarom kiezen? Het gaat uiteindelijk om meer flow: neem het beste van beiden.’

PROPOS als tool voor visueel kwaliteitsmanagement

Met behulp van PROPOS boekte Packo Inox snel resultaat. Kortere doorlooptijden, minder onderhanden werk en meer rust op de vloer. Maar dat was niet het enige voordeel voor Packo Inox. PROPOS blijkt namelijk ook een belangrijke rol te spelen in het kwaliteitsmanagement binnen Packo Inox. 'Wij gebruiken PROPOS ook om de kwaliteit te borgen en willen PROPOS meer en meer inzetten voor visueel management op de vloer.'

Packo Inox borgt kennis en kwaliteit met PROPOS

Packo Inox uit Diksmuide produceert industriële pompen en hygiënische componenten voor de voedingsindustrie. Vrij recent behaalde het bedrijf successen met de eigen Lean variant ‘creating flow’, waarmee zij de doorlooptijden voor de afdeling industriële pompen halveerden. Maar Lean was minder toereikend voor de high-mix low-volume productie van de afdeling hygienic components. Met PROPOS willen ze niet alleen de doorlooptijd verkorten, maar óók de kennis en kwaliteit borgen: ‘Niet meer continu brandjes blussen, maar proactief aan de slag.’