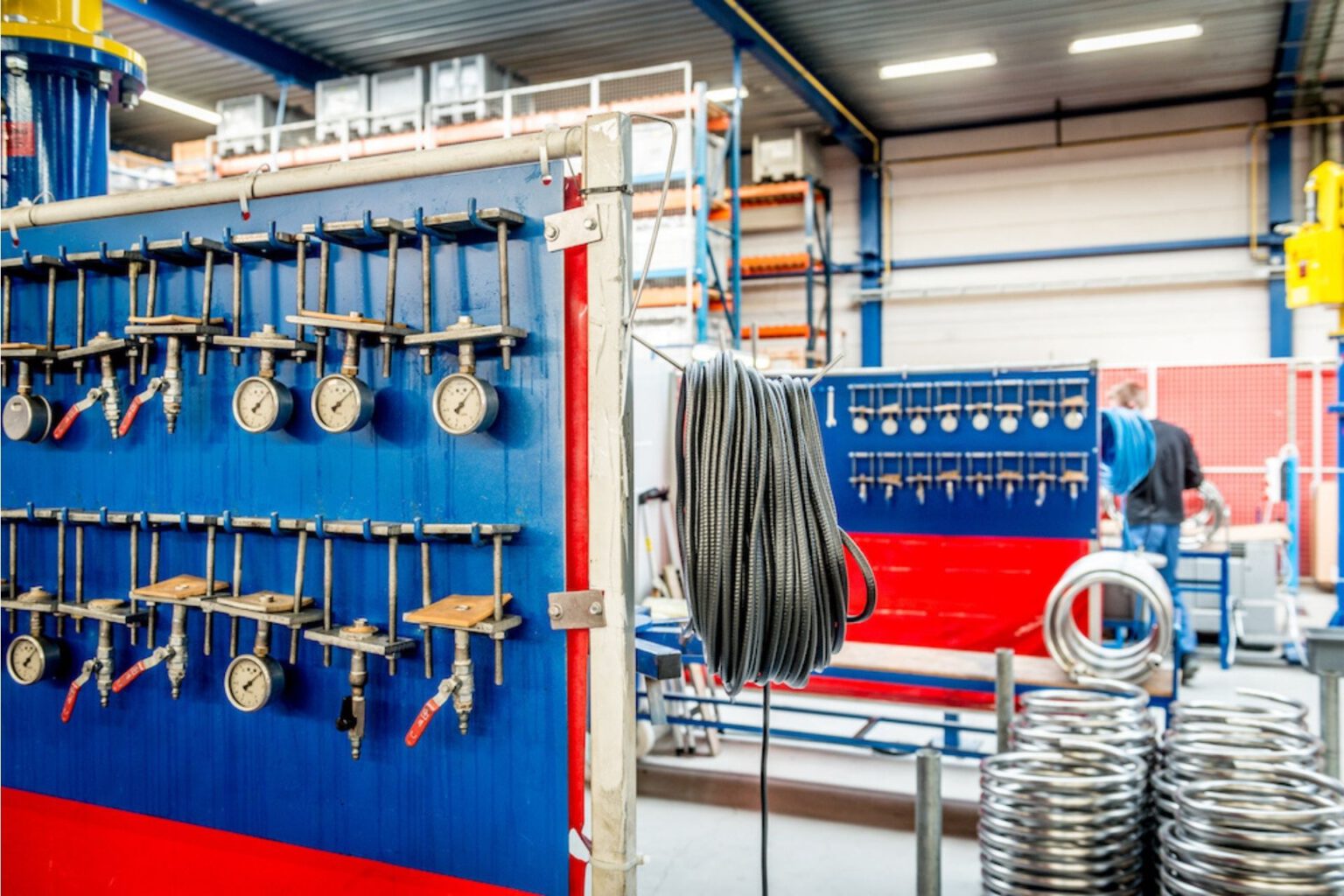

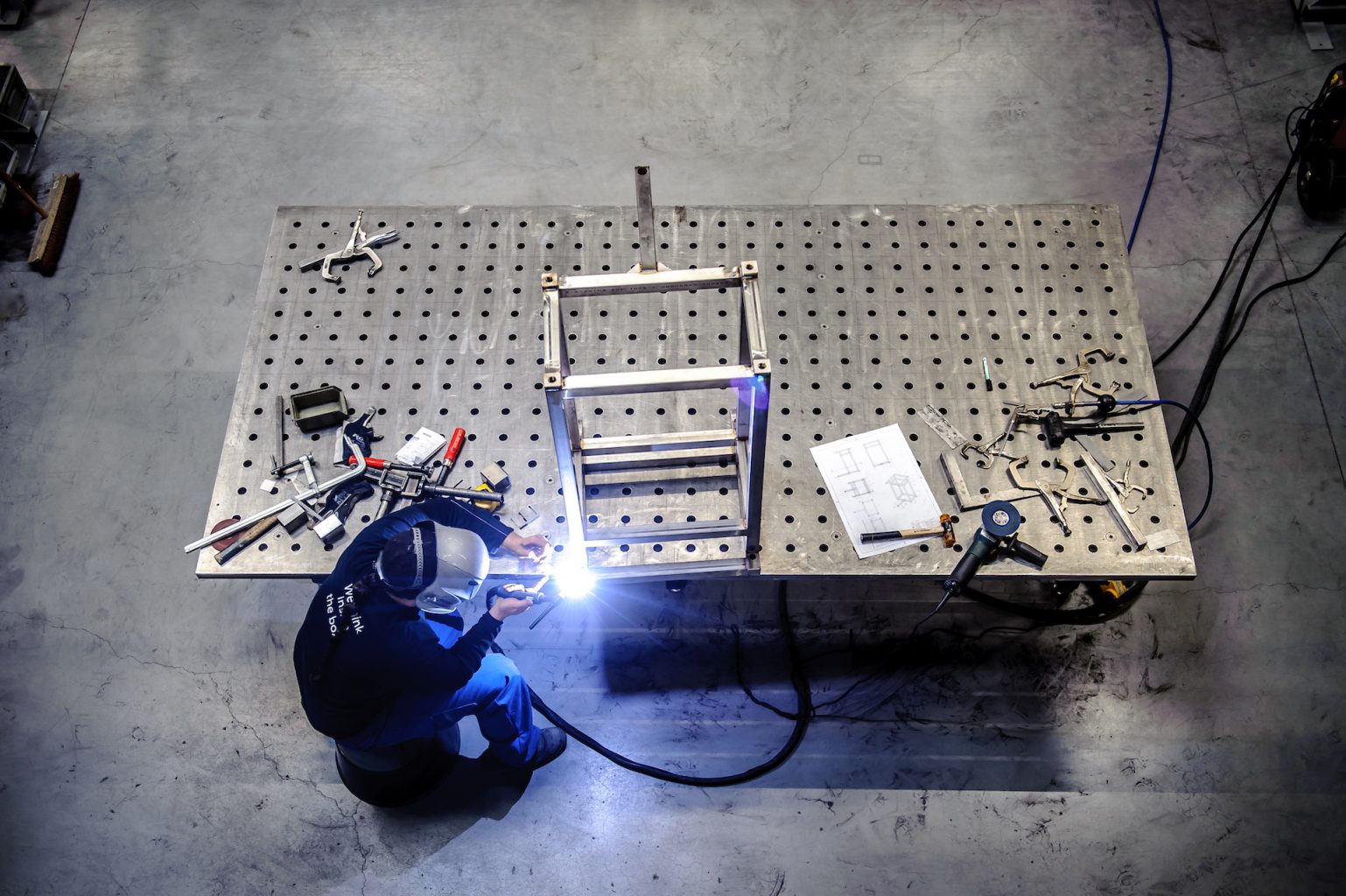

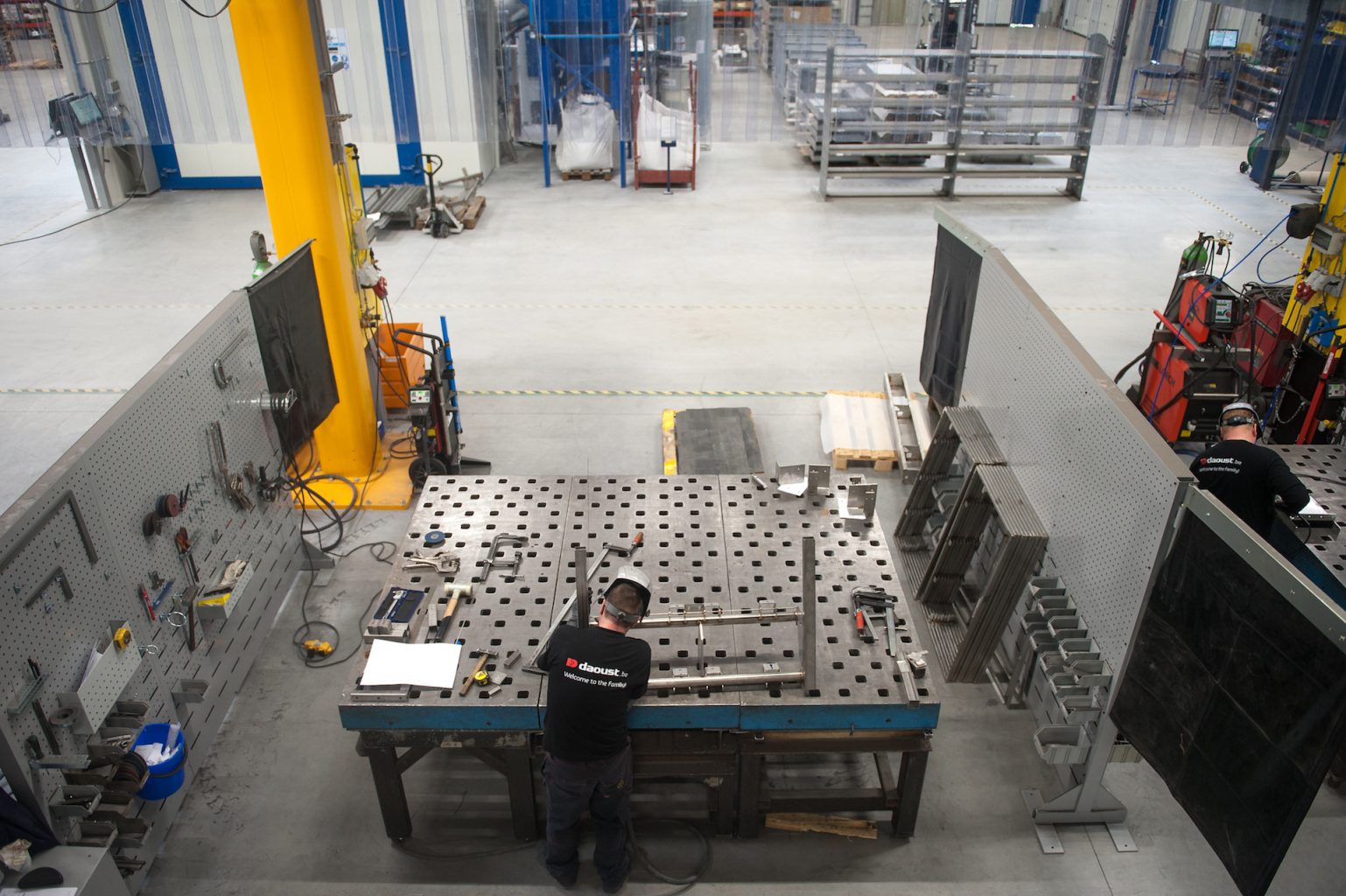

PMC has been a well-known name in the metal industry of West Flanders for over 30 years. Based at a brand-new location in the old Philips R&D building in Bruges, they recently started working exclusively as a job shop for Pattyn, a world player in the field of packaging machines and lines. Not so long ago, Jan Pauwels, Managing Director, changed course from large production quantities to smaller batches with a large variety: “QRM turned out to be the solution. With PROPOS we are taking the next step to work even more conveniently and faster”.

Making the decision: from QRM to shop floor control

“At the beginning of our partnership we were in a turbulent period. We moved to a new building and were so busy moving, installing and connecting the machines that the focus was no longer on the business. We started to lag behind on our delivery times. We had to intervene and decided to make a decision and team up with PROPOS. We were already working enthusiastically with QRM – we even have our own QROC center – and now we have the software to go with it”.

Simplifying the process

“Within two months we set up PROPOS with the information from our ERP system. Developing the connection took some time, but PROPOS was very helpful. We then divided up the cells in our factory. Which machines fit together? We were already working in cells before, but it had to be less complicated. That’s why we banged out half of the workstations with PROPOS. Fewer steps, but there can be more in each step. So you actually simplify your work process.

“When you install PROPOS, it’s also a good time to ask yourself: “What do you actually want to achieve? For us, that was to improve delivery reliability. When we went live, everyone quickly adapted with a little explanation. It only took a few days to get used to it, so it was not too bad.”

Clarity and time saving

“We used to walk around the factory to direct everyone. If a customer called with a change, we had to stop that work. That required a lot of work preparation, and also with quickly outdated data. PROPOS visualizes the entire work process and automatically plans the best route. That works a lot easier. The biggest gain is the clarity on the shop floor. That people are busy with what is most important at that moment. In PROPOS, the job that has to be done first is always at the top. We even place rush orders within 24 hours, without any problems. Thanks to PROPOS, we have thrown away all the rush cards that we used before.”

PROPOS in action: an example

“In week 1 I already saw that we would have a huge peak in week 8. In all areas. The workload would come to 180%. We immediately discussed this with the customer: which orders can we bring forward or put on a later date? We then adjusted them by one or two weeks and within a few minutes a new schedule was ready in PROPOS. Then you immediately see all the peaks disappear! Well, humanly speaking, you can never calculate what effect this will have on your production. But the software can! So that was very positive.”

Anticipating instead of planning

“We now look a few times a day at the information PROPOS offers. You get so much out of it. PROPOS continuously visualizes the workload, now and for the coming time. For example, we now see what impact a new order will have and whether there will be a peak in three weeks’ time. Then you can immediately anticipate this. Before that, we used to be unable to do that because we were overwhelmed by data.”

PROPOS put to practice: beyond expectation

“For one of our biggest customers it was necessary to deliver on time. The problem, however, was that they needed parts that we had never made before. You can estimate the production times a little bit, but you never know exactly. That’s where I entered the order in PROPOS and moved the due date forward a bit to be sure. We had to deliver on the 14th, so I put it on the 4th. So you can also set that manually. What do you think? We were able to deliver that order on Monday morning the 4th already for 99%. Of course our client was very happy with that”.

The benefits of PROPOS for PMC

“After only 2 months, I reviewed the balance: we had gone from 80% delivery reliability to 99.5%. In such a short time! That was fantastic, of course. In addition, we only had half of the work in process on the shop floor. So that’s twice as much space you save and twice as much time for not having to look for pieces! We’re also much less busy with planning and paperwork, which saves so much time. The overhead is a lot lower”.

Quick results for PMC

- from 80% to 99,5% delivery reliability

- 50% less WIP

- 50% less waste of time searching for parts

- Rush orders 2-3x times faster delivered (from 2-3 days to 24 hours)

Actively working with data

“We are really very satisfied with PROPOS. It is a big step forward for us. Much more is possible with the system. Not only can you extract information from it, but you can also actively work with it. If you see a backlog, what can you do with it? That is what we want to learn. That’s why we’re going to build up data first. Lead time, work in process, delivery reliability, quantities, these are data that we can extract from PROPOS in no time. We will continue to develop, we also want to work better organized in other areas. What can be done even faster? I think that’s the only way for our Belgian and Dutch companies to survive, by working smarter”.

About PMC Pattyn

Pattyn Metal Construction (PMC) is a well-known name in the Belgian metal industry. They recently started working as an exclusive supplier of sheet metal and welded constructions for Pattyn, a world player in the field of producing packaging lines. They work with high mix-low volume orders and are actively working on QRM, on their way to a “Factory of the Future”.

More cases about PROPOS?

Have a look at our customer cases! Recently we visited Packo Inox to have a look at the successes they have achieved so far with PROPOS. The result? Less WIP, shorter lead times and more ease of work on the shop floor.

More PROPOS news?

- Customer case study Merrem Kunststoffen

- Remote insight and grip on production: PROPOS at Merrem Plastics in Estonia!

- ‘Too much work in progress (WIP) is causing exploding lead times’

- Customer case System Flex: shop floor control and automation of processes

- Customer case OTM-Zenith: shop floor control for the printing industry