It's all about time

Do you work according to the methods of Lean Manufacturing or QRM? Or are you looking to implement them in your company? PROPOS helps you to implement these work flows and helps to continuously improve your processes.

PROPOS is based on the philosophy of Quick Response Manufacturing (QRM). QRM is the continuous reduction of the lead time. Waste disappears from the system. QRM uses the same techniques as Lean Manufacturing but focuses on customer order-driven production companies with step-by-step production, high product variety, and strongly changing order sizes.

Quick Response Manufacturing (QRM)

The founder of QRM is the American prof. Rajan Suri. He also developed the POLCA system to guarantee order flow in the production process. PROPOS has a digital version of POLCA so that you can implement it quickly and easily. Also read: What is QRM?

For more information about Quick Response Manufacturing, visit:

QRM Wiki

Website of Rajan Suri

The Fabricator on cellular production

In which way is QRM supported by PROPOS?

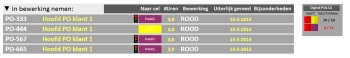

PROPOS software is the first specific QRM software in the world! PROPOS supports the cell thinking of Quick Response Manufacturing and helps you make a QRM planning including authorization moments. The dynamic QRM production planning is then continuously monitored so that you only have to deal with the exceptions. The exceptions are production orders that risk not being able to meet the production planning made.

PROPOS, QRM and Lean

Are you not yet involved with Lean Manufacturing, QRM or something similar? Then PROPOS can still help you solve the issues mentioned on this website. If you are just starting with Lean or QRM, PROPOS enables you to realize that implementation faster and better. Is your company well advanced with this matter? Even then, PROPOS helps you to take it to a next level for even better results.

Want to know more about Quick Response Manufacturing? Prof. Rajan Suri’s book “It’s about time” is a good explanation. However, it is not necessary to be already working with QRM to start with PROPOS. When implementing PROPOS, we automatically apply principles of QRM, such as dividing the production floor into QRM cells. Whether you’re a beginner or an expert in the QRM field: PROPOS helps you advance with optimal flow.

Digital POLCA

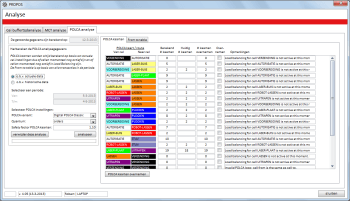

Digital POLCA can be an effective tool to further optimize your work processes. PROPOS has a unique and advanced Digital POLCA module so that the introduction of the powerful POLCA system can be realized quickly and easily.

POLCA cards are digitally managed and digitally displayed on your work floor. In the event of a shortage of tickets, the relevant POLCA routes are automatically blocked.

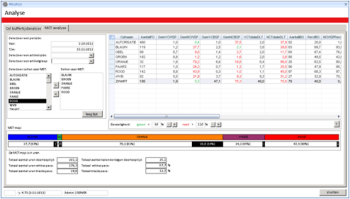

PROPOS helps you calculate the number of POLCA cards. This can either be based on historical data as collected by PROPOS, but also on the basis of the current situation in your workplace. This makes starting with POLCA even easier. PROPOS also helps you achieve your QRM objectives in the analysis. One of the components is the generation of an MCT folder at the touch of a button.

QRM production planning

for faster lead times

QRM production planning helps you to produce faster and more efficiently. Especially when you are experiencing difficulties streamlining the production process because you produce many variations in smaller quantities (high mix-low volume). PROPOS proves itself in practice daily. Want to see for yourself how it works? You and your employees are more than welcome to visit us. Enter your details, and we will contact you as soon as possible.