Strategic

PROPOS is a unique concept for detailed planning and control in the workplace. It actively improves flow in the workplace and creates a pull production. PROPOS collects valuable information for performance measurement and analysis that you can use for continuous improvement on the road to world class manufacturing.

Measure easily

Results

You gain insight into the whitespace and blackspace of production orders. This allows you to implement targeted improvements and achieve results.

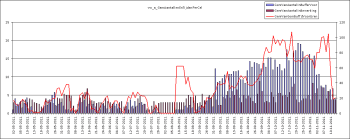

Bottlenecks

PROPOS provides clear insight into problem areas in your production process. This makes it possible to take action for an optimal flow.

Capacity

You know exactly how much work is planned in the coming period, and how many people you need for the job. You can anticipate peaks in the workload.

Cost reduction

Thanks to the data that PROPOS collects about your production process, you can tackle specific problems and cut costs.

For the (strategic) management

A wealth of information

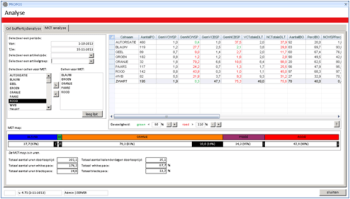

PROPOS collects a wealth of information about the processes in your factory. You can analyze this information, to help you make the right (strategic) decisions. The possibilities are practically endless. For example, you can find out more about bottlenecks in your factory and when they arise. You can map waiting times and lead times of orders in every part of your factory. You can also easily monitor your internal and external delivery reliability.

All this data helps you to make decisions about how you can further shorten your delivery times and further increase delivery reliability. You can make better decisions about investments that should or should not be made.

PROPOS collects a wealth of information for analysis

PROPOS effortlessly creates MCT maps

Articles

Merrem Kunststoffen is Europe's top player in the processing and supply of technical plastics. With advanced machinery and 24/7 production, the turning and milling company is fully committed to robotization and automation as the key to success. 'Within 2 days we were live with PROPOS, with no downtime. We soon noticed that the production numbers went up and the flow is a lot better.'

‘Too much work in progress (WIP) is causing exploding lead times’

A shop floor full of orders and machines that are scheduled at a maximum capacity; it seems an ideal image for a shop floor to be busy and to get the most out of your machines. In practice, however, this leads to unnoticed negative consequences. Long lead times, employees searching for missing parts and work that stands still for an unnecessarily long time. And that results in customers having to wait too long for their orders. Quick wins can be found in tackling work in progress. In fact, less work-in-progress means better workflow and shorter lead times.

Customer case System Flex: shop floor control and automation of processes

System Flex produces state of the art partitions and ceilings. Custom made, with their own glassware and window frames. All this with a delivery time of just three weeks. With PROPOS those delivery times are more easily achieved. In addition to our fully automatic shop floor control, we have implemented custom apps for the automation and digitalization of production process, saving a lot of time for System Flex. Sven Damen, Project Coordinator: ‘From the first week that we went live, we saw improvements.’

Customer case OTM-Zenith: shop floor control for the printing industry

OTM-Zenith from Brussels is the Belgian market leader in the stickering and decorating of machines, vehicles and buildings. Think of signage materials for ambulance and police cars, but also decorative and functional materials for the automotive industry and machine builders. In addition, OTM is the supplier of the official Belgian license plates. Every day, about 700 orders are in production, in varying sizes, over different stages. "Then you need a system that can handle such a volume," emphasizes Managing Partner Kurt Persoons.

Customer case PMC: shop floor control and QRM

PMC has been a well-known name in the metal industry of West Flanders for over 30 years. Based at a brand-new location in the old Philips R&D building in Bruges, they recently started working exclusively as a job shop for Pattyn, a world player in the field of packaging machines and lines. Not so long ago, Jan Pauwels, Managing Director, changed course from large production quantities to smaller batches with a large variety: "QRM turned out to be the solution. With PROPOS we are taking the next step to work even more conveniently and faster".

Productieprocessen automatiseren met de Custom Apps van PROPOS

Een digitale fabriek met PROPOS? PROPOS maakt het werk voor productiebedrijven een stuk makkelijker. Duidelijke prioriteiten op de werkvloer, een volautomatisch aangestuurde planning en waardevolle data inzichten in uw gehele productieproces voor continue verbetering. Maar waarom zouden we daar ophouden? Met onze Custom Apps is het mogelijk om elke gewenste functionaliteit in PROPOS te integreren. Dit zorgt ervoor dat u veel productieprocessen kunt automatiseren. Van kwaliteitsmetingen tot het afboeken van materialen. Eén systeem voor uw hele bedrijf. Op weg naar een volledige Smart Factory!