Digital POLCA

PROPOS is proud to be the first in the world to present a digital POLCA system! More powerful than the version with physical cards and much easier to implement. Will POLCA help your company? Let’s find out!

Digital POLCA module

PROPOS has powerful load balancing systems to balance and guarantee the flow of orders in your factory. One of those systems is a digital version of POLCA. PROPOS Digital POLCA is the first in the world to present a powerful method of ‘ramp metering’, so that no traffic jams occur in your factory and your production orders are guaranteed an optimal flow! Consequently, your work in process position and your delivery times benefit greatly. We would be happy to explain everything to you personally about the power and operation of this system. Below you will find an introduction.

Why POLCA?

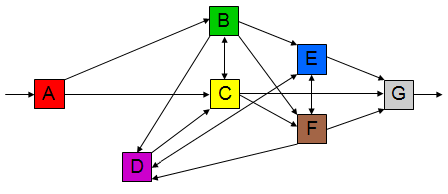

If your company is characterized by the production of (many) different products in separate series (batch production), then the production orders in your factory will not always use the same machines or operations. In other words: orders follow an individual route through your factory. Therefore, it is likely to have a lot of work in process, that mistakes will be made and that lead times are quite long and unreliable. Your ERP system or planning program most likely does not offer you grip on your situation. Let’s explain this routing with a visualization.

The image below shows a schematic representation of a factory with a ‘spider web’ situation. Orders can arrive via various routes from A to G. This scheme may already seem complicated for your factory. However, if you would write down the different paths of your production orders, you will probably come to even more variants. You can easily lose grip even in less complex situations.

What is POLCA for production?

The reason that such problems occur is that for various reasons jobs cannot always be predicted exactly in the way in which they go through the factory. For example, because pre-calculated setup times or processing times are incorrect, because your operators do not always work at the same speed, due to sickness and their possibly less experienced replacements. Or it could simply happen that a machine malfunctions or works at half speed. In summary: your actual situation on the work floor differs from your schedule.

The result is that you can never predict exactly which order will be where at what time and when it will be ready. As a result, orders will accumulate in your factory in certain places. Orders stand still longer than anticipated. More mistakes are made. Your delivery times and your production costs are rising. You suffer from backorders.

POLCA has been developed to solve this situation. POLCA is a production control system and stands for Paired-cell Overlapping Loops of Cards with Authorization. Prof. Rajan Suri at the University of Wisconsin (USA) developed POLCA. Like Kanban and Conwip, POLCA is one of the pull systems. Using physical cards, POLCA ensures that departments or ‘work cells’ as Rajan Suri calls them, only deliver to the next cell if this cell has issued a capacity card (signal ‘you can deliver’) to the delivering cell. If the card is missing (signal: ‘no capacity available), the higher cell may not deliver. The system thus prevents accumulation of work in your factory. The result is that all orders on the shop floor reach the end point as quickly as possible. POLCA ensures that a pull system is created in your factory (pulling orders from behind) instead of a push system, whereby orders are pushed into the system from the front.

How does POLCA work?

Disadvantages of traditional POLCA

POLCA is, as stated, a very powerful system that can be of great value for your production process. There are, however, also practical disadvantages to it:

What are the disadvantages of POLCA?

- It requires a lot of education and training from your people before they can understand and apply the POLCA system in your factory

- Dozens of cards must be designed, printed and laminated in such a way that they will last on your shop floor

- Signs must be placed everywhere in your factory where the cards can be placed and collected

- For many companies, it is difficult to determine the exact number of cards required for each route beforehand. The number of cards is later hardly adjusted in practice, which in turn has a negative effect on the effectiveness of the system

- It requires discipline from your employees to continue using the cards

- A lot of work must be done to keep the POLCA system up-to-date in changing circumstances in your factory

Digital POLCA benefits

That is why PROPOS has developed Digital POLCA. It combines the power of POLCA with the benefits of a digital system.

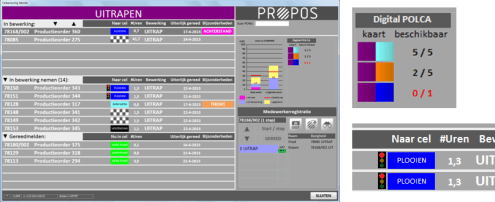

Working with POLCA is nothing more than enabling the Digital POLCA module and configuring it. Then PROPOS immediately shows the employees in your factory, using simple visual signs, whether or not a certain order can be processed depending on the available capacity downstream. Rate dosing to the next step and the orders in your factory continue to flow.

Implementing and keeping POLCA up to date in your factory has become an easy and logical step with Digital POLCA!

PROPOS is the first in the world to develop the digital POLCA system!

How even your factory can get stuck

Do you want to see for yourself how your factory can get stuck due to unpredictable circumstances? Click here for a detailed example.