When I visit companies or when I attend seminars, sooner or later, it’s all about “pull production”. What is it, what are the benefits and how do you easily create a pull production?

To answer that, we need to look at how production is traditionally planned and managed. A production planning in the traditional sense includes a planned start and end date for all orders to be produced per operation. These are calculated in advance on the basis of the estimated number of hours of work per operation and possibly a number of theoretical optimizations. Orders are sent based on this schedule; the first operation must start on the first scheduled start date and end on the first scheduled end date. The order is then transferred to the next department where you can see on the schedule when the order should start and end there. We call this principle a push planning; orders are pushed through the system from front to back.

Bottlenecks

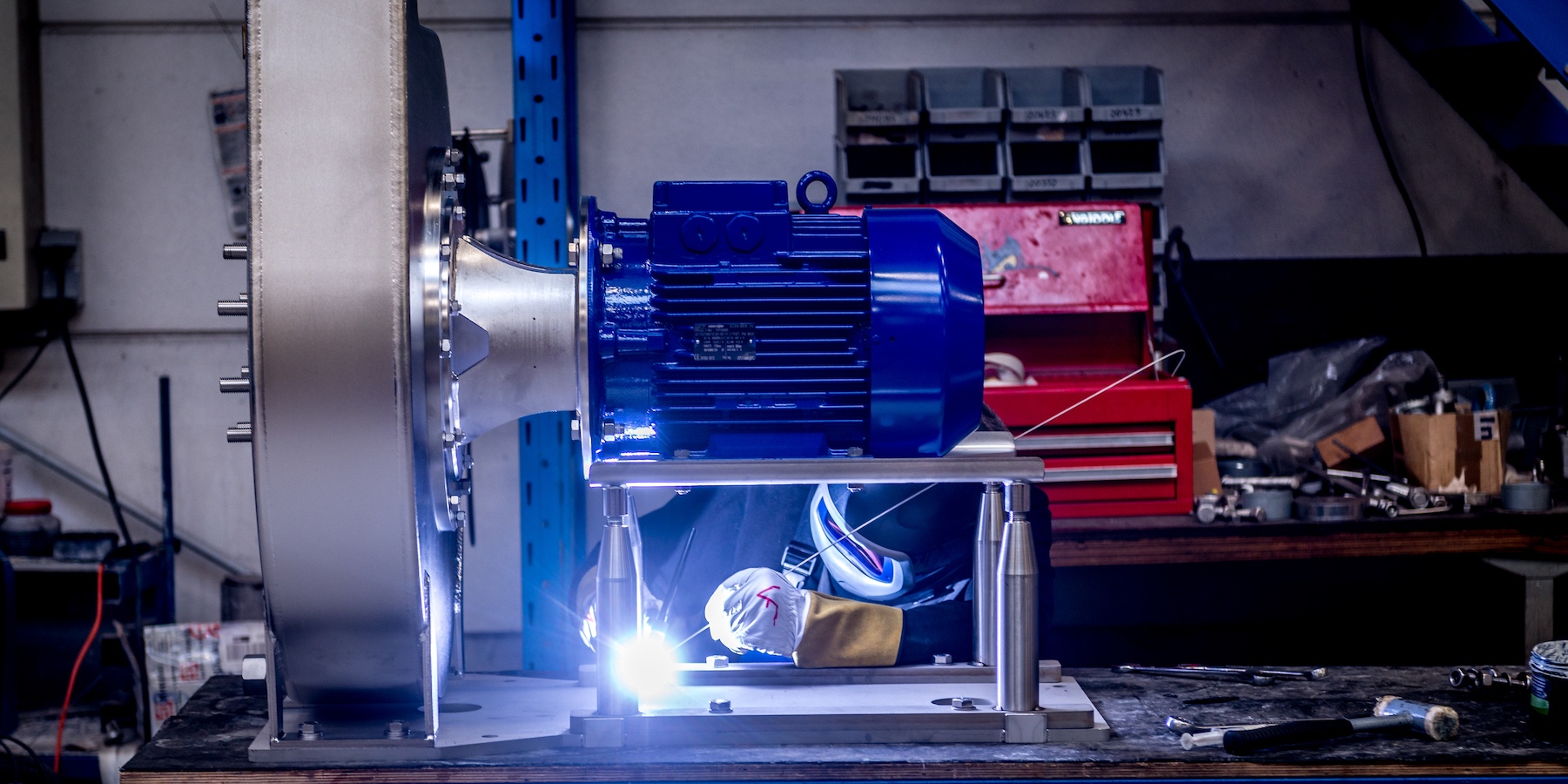

The disadvantage of such a push production is that you also keep pushing work towards directions where it is already too busy. A traffic jam of waiting orders occurs, and it takes more and more effort to get the orders processed through the factory. It is as if you are increasingly trying to push them through a funnel; accumulations occur, and it takes more and more power.

View of bottlenecks

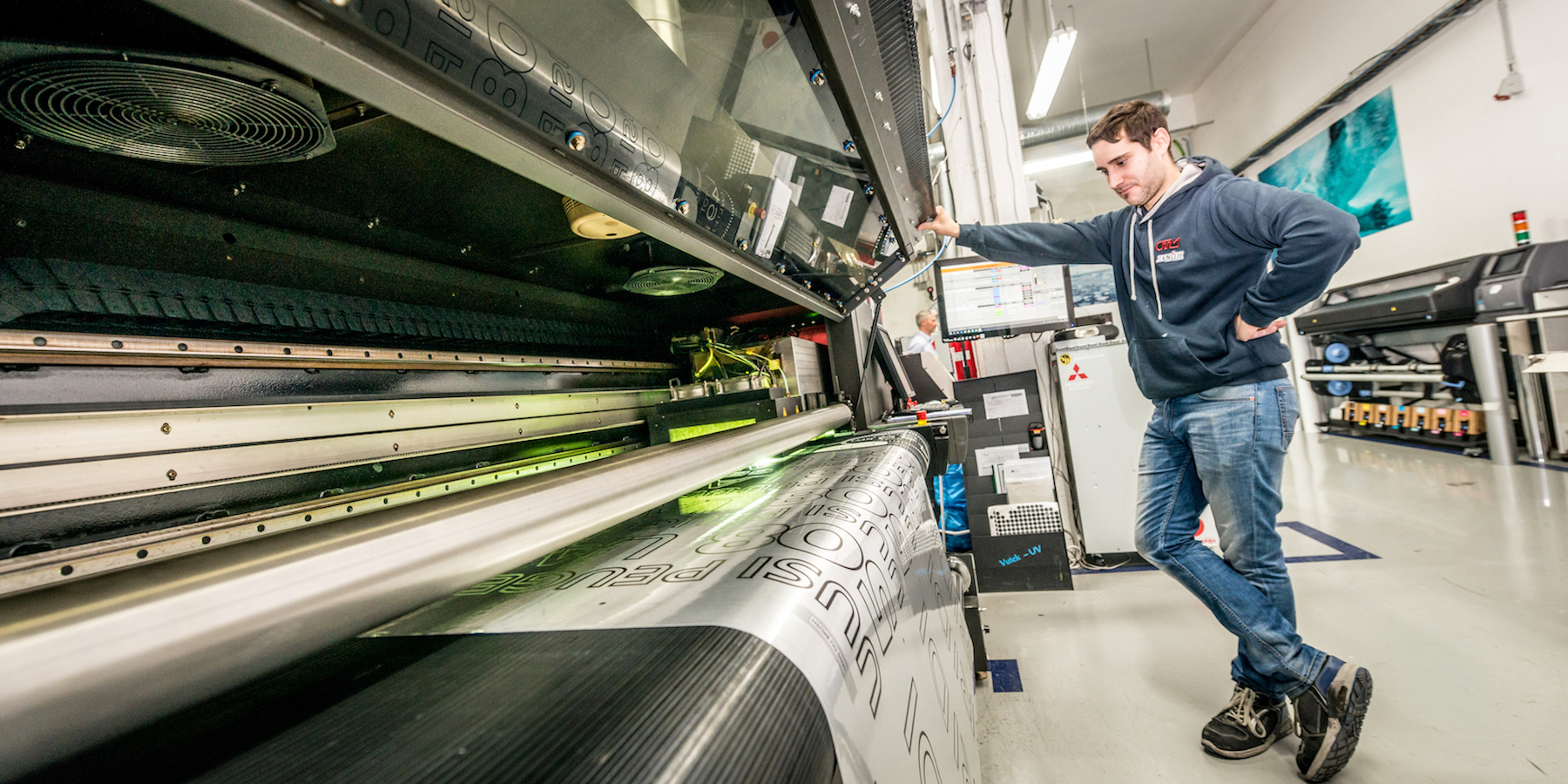

The alternative is a pull production, like described above. PROPOS can implement this for you, making sure you achieve optimal flow. In addition to this mechanism, the Digital POLCA module can also be switched on. This optional mechanism ensures that floating bottlenecks are detected. Upon detection, other routes through the factory are first utilized, so that the production management can help remove the bottleneck. In this way, valuable time that would have been lost by working on orders, that would otherwise have been sent to a bottleneck, is used for orders that can then continue their way smoothly.

Result

The result of a pull production is that the flow of orders on the shop floor increases and fewer exceptions occur (for example, production cells that have more work planned than they can handle ). Moreover, it will not cost you extra effort, as it is arranged automatically for you. This way, creating a pull production is no more than setting up the system and responding practically and decisively to the reports the system gives.

So, what is pull production? Compare it with how a river flows: gravity-driven, always looking for the road with the least resistance. In your production, you use ‘pull’ to ensure that your available capacity is used as optimally as possible to increase the flow of orders.