Tip 15

tip #15

WIP analysis

Did you know that the WIP analysis tool in PROPOS can be used to reduce the work in process in production even further and thus shorten your lead times even further? This is because the amount of WIP can be directly related to your lead times!

The correlation between WIP and longer lead times

Imagine what happens when you utilize the highway to the full 100 percent. You then have traffic jams. In a traffic jam your speed goes down (sometimes you even stand still) and if you would measure the output at a certain point, you will notice that the output also goes down. This is exactly what often happens in a high mix/low volume job shop. We often create our own traffic jams by scheduling all machines as full as possible, which results in long lead times and a lot of work in process. Quick Response Manufacturing (QRM) teaches us that when you use more than 80 percent of your capacity, your lead times will explode, exponentially.

In other words: Too much WIP results in longer lead times.

Less WIP = shorter lead times

This means that lowering the WIP will result in shorter lead times! The WIP analysis tool helps you to get insight in where you can best reduce the WIP.

The WIP analysis tool can be used to follow the course of the cell process. The amount of WIP can be directly related to the amount of white space in your processes. Too much WIP leads to (too) long waiting times. Not enough WIP results in low efficiency or can even lead to standstill of cells.

How does the WIP analysis tool for shorter lead times work?

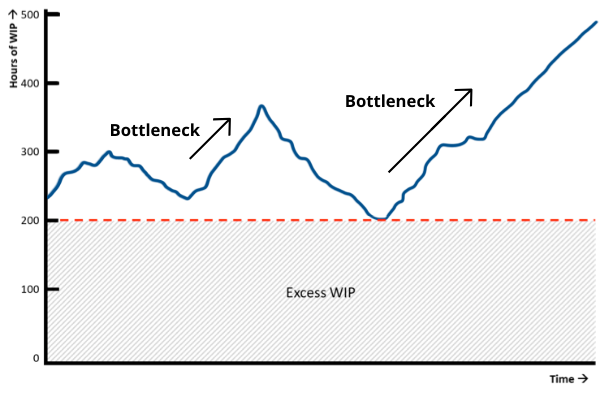

The line in the WIP analysis tool will increase by the amount of pre-calculated processing time when a job enters the cell and decrease by this value when a job leaves the cell. If there is not enough capacity in a cell, more work goes into the cell than goes out, because the limited capacity cannot process the WIP. If the WIP line is constantly increasing it means that the selected cell is most likely a bottleneck, or at risk of becoming one.

In situations where the amount of WIP over a long period of time does not drop below a certain number of hours – let’s say 200 hours – a reduction in the amount of WIP may be desirable. Such a situation indicates that there is too much WIP in the cell. Reducing the WIP results in less white space and will result in a better flow. Reducing WIP will also result in less working capital and more space will become available on the shop floor. In the example below, this will mean that the amount of WIP can be reduced by at least 200 hours, without negatively impacting the processes within that cell.

How can the WIP be reduced with the analysis tool?

The amount of WIP between certain cells can be lowered in PROPOS in different ways.

- Authorization: The first way is to authorize jobs before they enter the shop floor. When someone then detects that the WIP in the cell reaches a critical level, the authorization will have to stop. How to activate this function in PROPOS can be found in the manual, chapter 11, Part A, section I22-I29.

- Digital POLCA: Another and less intensive method is activating the Digital POLCA module in PROPOS. POLCA then automatically stops the order flow to the cell when it appears that the WIP level has reached the critical point (that is when the POLCA cards have run out). More about the explanation of POLCA can be found in the PROPOS manual, chapter 9, section J.

More WIP and Polca?

Also, watch also our video on reducing WIP through POLCA:

Want to go into more depth? Here you can watch the whole case study of Julian’s presentation about POLCA, Lean and QRM at Kooima company, Iowa.

More PROPOS

Want to know more about PROPOS? On LinkedIn we regularly post videos, articles and cases.