By Julian Stark, Quick Responsive Manufacturing advisor

Picture what happens when you utilize the interstate at a 100 percent capacity. You have a traffic jam! In a traffic jam your speed goes down (sometimes you’re even standing still) and if you would measure the output at a certain point, you would find that the output goes down also. This is exactly what happened in our high mix/low volume job shop. At Kooima we created our own traffic jams by planning all machines as full as possible, resulting in long lead times, and a lot of work in process. Quick Response Manufacturing (QRM) teaches us that when you utilize capacity with more than 80 percent, your lead times will explode. PROPOS has proved QRM right.

“At Kooima Company, we were looking for ways to decrease our lead times and improve our on time delivery performance. I started using LEAN manufacturing, but soon found that most of the LEAN tools did not fit our high mix, low volume job shop environment. I started to do some research and found out about how Quick Response Manufacturing (designed by Prof. Rajan Suri from the Wisconsin University in Madison) could help us reduce our lead times by reducing work in process with POLCA.

We implemented the physical version of POLCA and were able to decrease our WIP by a lot. However, managing the physical tags required much work. The tags would easily get lost, get smeared, and had to be physically put back in the slot of the upstream cells. It was also very easy to cheat the system. We struggled to roll out POLCA between more cells on the floor.”

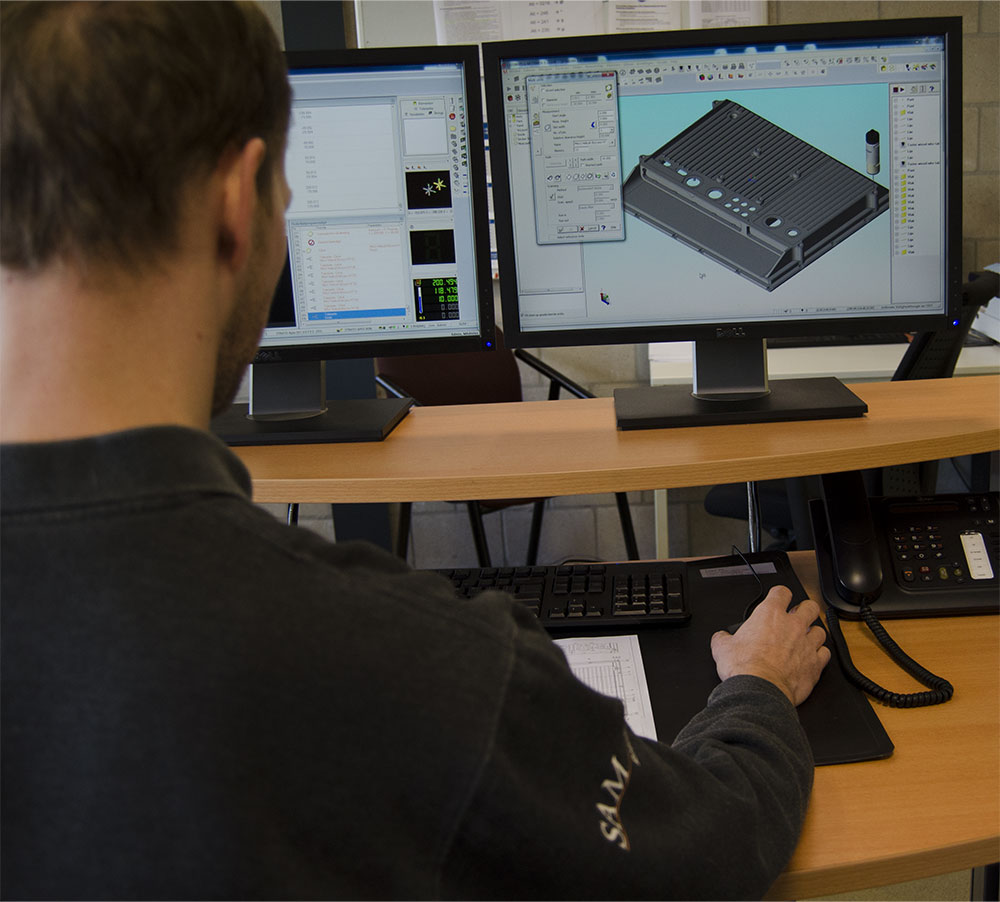

“We come across this shop floor control system, called PROPOS software. PROPOS has an optional module called Digital POLCA. Immediately we felt PROPOS could be of great benefit to Kooima, and after a visit by PROPOS, we were all excited to get started. Soon after, we started with the implementation.

We implemented PROPOS and with Digital POLCA it became much easier to manage the tags, taking less manpower to control. With PROPOS it has been very easy to roll out POLCA between more operations. POLCA helps us to quickly respond to capacity issues out on the floor. By cross training our people, we can ask our employees to help in an overloaded workstation to get rid of the bottleneck.”

Teamwork

“PROPOS was up and running within six months. Connecting to our ERP system Epicor went smoothly. The operators adapted quickly, because how PROPOS works is very easy to understand and straight forward. We worked together for six months to connect PROPOS to our ERP system Epicor and (re)design the production processes of Kooima. I liked how the people from PROPOS were so actively involved, not just with implementing the software but also with other practical matters. Because they have a lot of practical experience and knowledge, they can provide professional advice on how to improve your processes with Quick Response Manufacturing. PROPOS really helps you beyond the implementing software. We went live quite fast, mostly because our IT team and PROPOS were both on top of it.”

How PROPOS has benefited Kooima Company

“Starting or completing jobs with PROPOS was easier than ever and we have a lot more useful information available in production. We already noticed results after using PROPOS for about two months. We were able to decrease work in process in most of the cells. With PROPOS it became a lot easier to make sub parts of an assembly flow together on time. And the lead times became shorter, causing our company wide on time delivery performance to improve with about 40 percent!

PROPOS offers many visualizations. For example, PROPOS shows how the work in process on the floor affects our lead times. And we can see the upcoming ‘traffic jams’, which helps us to prevent that bottleneck from happening. We will use all that information to keep improving our processes.”