Last week we were in Estonia for the kick-off of the PROPOS implementation at Merrem Tööstusplast in Vahi! This state-of-the-art Estonian manufacturer of customer-specific plastic materials is already promising the fastest possible delivery times, and with PROPOS, not only will the promise be better kept; Merrem will be able to deliver even faster! In fact, our production planning and jobshop execution system will shorten lead times, reduce overhead costs and improve delivery reliability for Merrem’s sales territory in Eastern Europe. The big advantage of the implementation at their site in Estonia is that the Merrem Plastics Group can now monitor and adjust the planning remotely, from the Netherlands, without any effort!

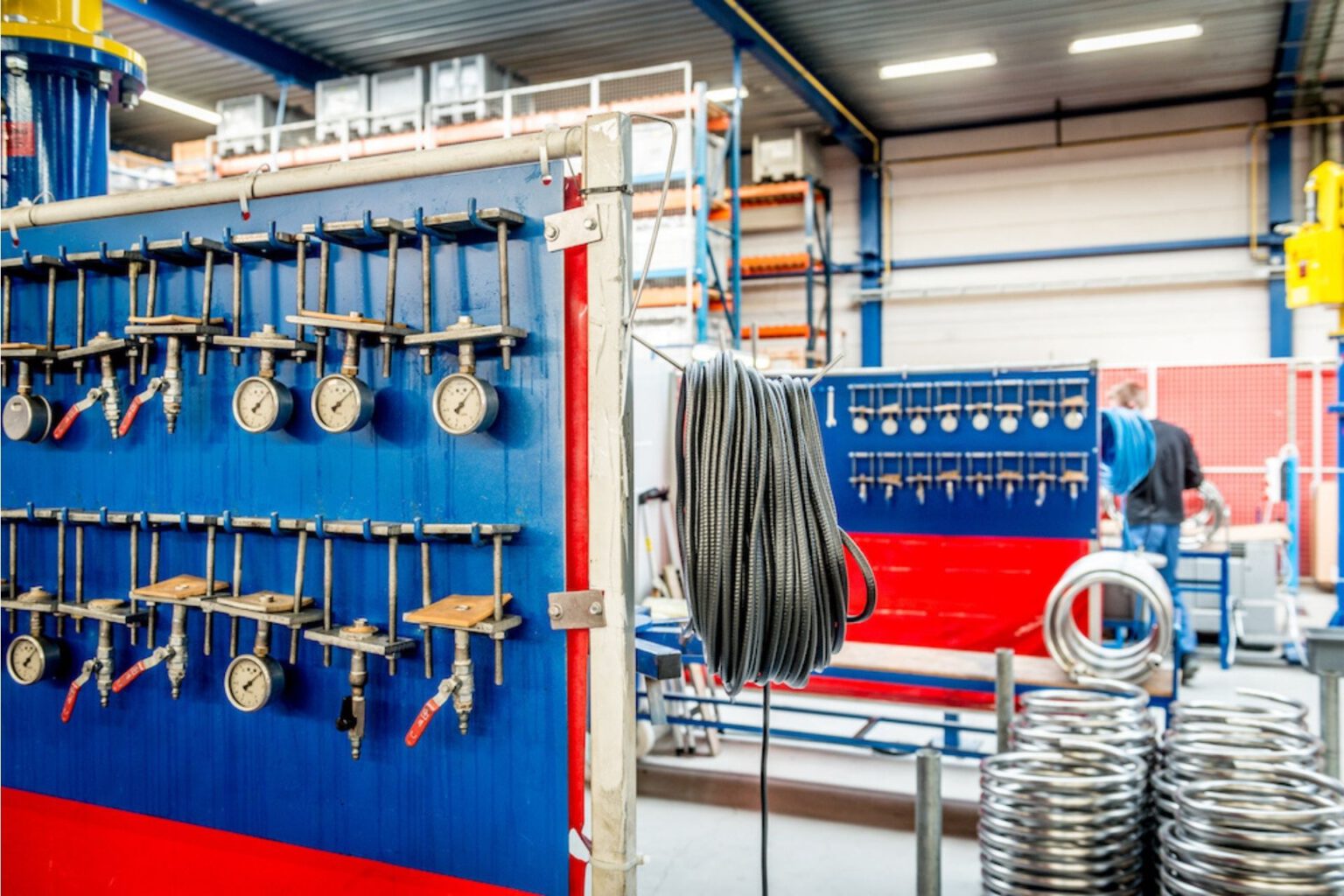

High-mix low-volume production at Merrem Tööstusplast

Merrem Tööstusplast is a specialist in the processing and supply of all kinds of plastics to Eastern Europe. These include various wear-resistant, construction, transparent, fluorine, high performance plastics, but also composites and thermal insulation materials. The company has a state-of-the-art machine park with its own machining department with the most diverse CNC machines. This allows the company to work in a customer-specific way and make the desired products based on their customers’ drawings. From single pieces to large series: Merrem delivers custom-made plastic materials with the fastest possible delivery times.

Smart manufacturing processes and automation

To achieve this, the company works with smart automated processes. For example, several machines have robotic arms that put the product into the machine themselves, and also take it out again when the milling or turning process is finished. PROPOS will further secure and accelerate these fast delivery times by allowing parts to come together just-in-time and reducing lead times. In addition, this will allow Merrem Tööstusplast to be even more flexible in responding to customer demand in Eastern Europe!

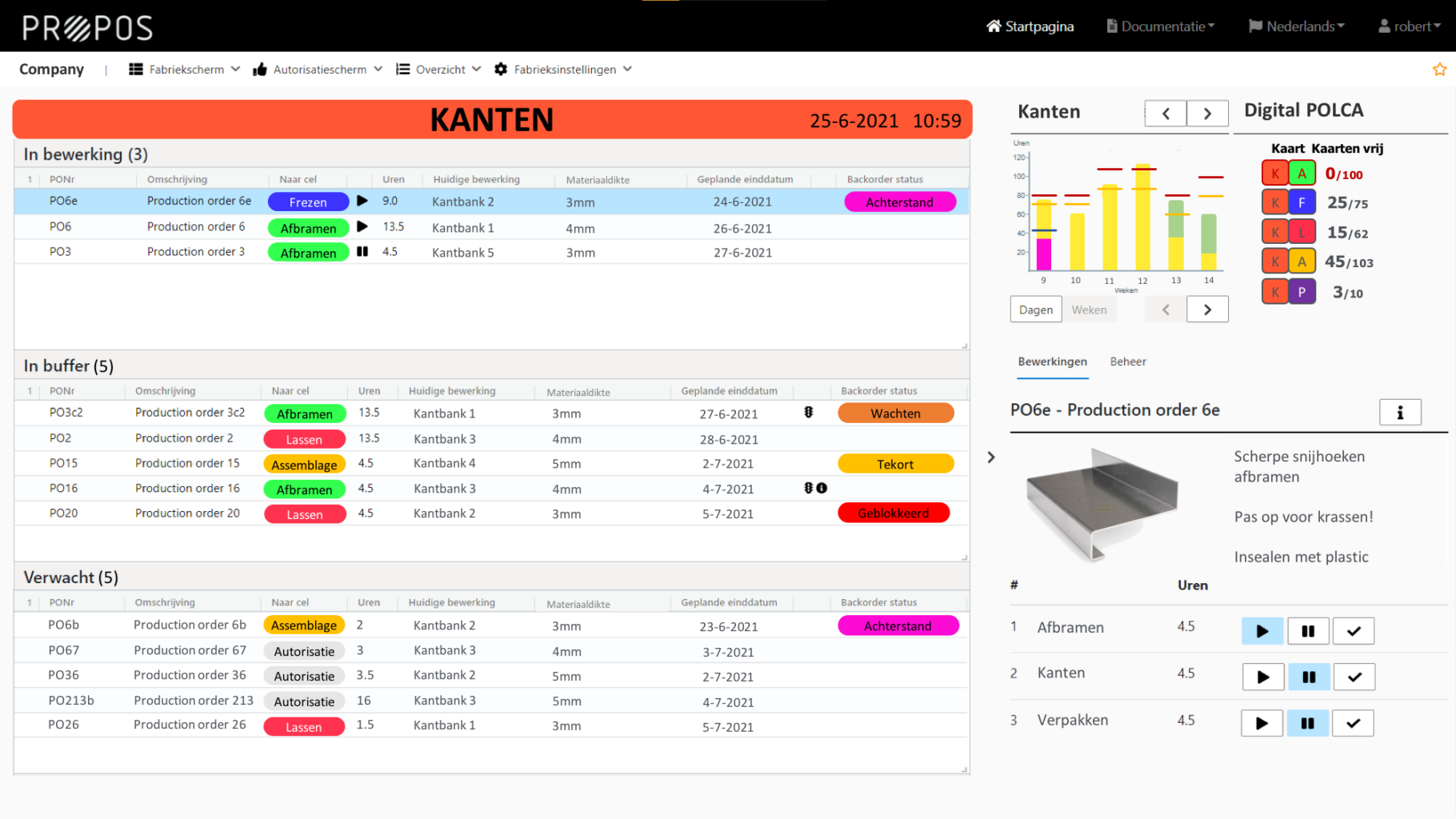

Realtime remote insight into the entire production process

Since 2014, Merrem Tööstusplast has been part of the Merrem Plastics Group with branches in the Netherlands, Estonia, Latvia and Germany. The company is one of the largest producers of technical plastics in Europe. At the end of 2021 the Dutch branch Merrem Kunststoffen from Dinxperlo already chose the fully automated production planning and shop floor control of PROPOS. After just six months he company was so pleased with the results that they decided to wait no longer and implement PROPOS in Estonia as well.

A big advantage of implementing PROPOS with their Estonian colleagues in Vahi is that it allows the Merrem Plastics Group to remotely monitor and control planning from the Netherlands without any effort. Thanks to the PROPOS cloud, the company has real-time and remote insight into the status of every production order and production cell.

Unnecessary waiting time in the production process

During our stay, we conducted the first training sessions to the employees of Merrem Tööstusplast, covering some of the lean and QRM principles of PROPOS and the role of work in progress (WIP) and unnecessary waiting time in the production process. The reactions of the staff were also very enthusiastic in Estonia! They also see that PROPOS brings a lot of clarity, overview and especially more flow to the work floor.

“Previously, the approach was always to schedule machines continuously full and keep them running, ‘because no money is made with downtime’. Thanks to the insights of PROPOS, Merrem now looks at this differently. That’s why the company wants to actively focus on cross-training their staff, and ensure that, for example, the sawmill starts to supply the factory better just-in-time, in order to actively reduce work in progress.” – PROPOS at Merrem Kunststoffen NL

This summer, we go LIVE!

After the pleasant cooperation in the past days, we conclude our stay in Estonia with a well-deserved visit to beautiful Tallinn, before we return home with a feeling of contentment. The project looks very good! Since the production processes, machines and approach in Estonia are almost the same as at Merrem Kunststoffen in The Netherlands, we expect a smooth implementation. We plan to visit Estonia again in August to go LIVE!

Thank you for your hospitality and the pleasant cooperation Merrem Tööstusplast, Aitäh!

Rapid implementation thanks to plug and play connection with Ridder iQ

At Merrem Tööstusplast PROPOS is linked to the ERP system Ridder iQ from ECI software solutions. Because we already have a default plug and play connection, we can go live very quickly!

More Merrem Plastics?

Meet Merrem Plastics!

Back to home